|

||

|

||||||

The highly directional patch antenna on the XCam's transmitter wasn't a good choice for my R/C model. The transmitter needed an omni antenna that would mount under my helicopter, which meant it would need to take a beating from hard landings. So, I removed the transmitter's "Mickey Mouse Ear" patch antenna and created a simple rubber duck antenna. This DiY antenna is a vertical coaxial design. It is very flexible so it can withstand a lot of abuse, but it has much lower RF efficiency than a traditionally made dipole (note: If you want longest range then use a common dipole or other omni antenna of your choice). It is built from a carefully stripped piece of miniature RG-174 or RG-178 50 ohm coax cable. The photos show each wire stripping step that are used to create the antenna.

|

|

|

Step A: Using a 8 inch long piece of RG-174 or 178 coax cable,

strip away two inches of outer jacket from one end. Do not damage the shield!

Step B: Carefully push the shield down. Avoid unraveling the shield's braid as you do so. Step C: Continue pushing it down. It will now start to "turtleneck" over the coax's jacket. |

A

|

B

|

C

|

|

|

|

|

Step D: At this point it has been fully folded back over the jacket.

Using a 25 to 37 watt soldering iron, tin the braid area that is about 1.2"

back from the fold-over. This will stop the braid from unraveling.

Step E: Trim the coax's shield and center conductors to 1.17" long each (1/4 wavelength). Measure carefully! Step F: Place a 2.5" long piece of heatshrink over the end. You just made a coaxial Rubber Ducky style antenna designed for 2400Mhz use. |

D |

E |

F |

The antenna is soldered to the XCam2 board in the same fashion as the original. Pay close attention to your soldering, since if you melt the coax's inner dielectric you will degrade transmit power. The end that solders to the XCam2 must have very short connections and plenty of shield-to-ground surface area. Just take a look at the original's mounting to get a feel for how you should solder it in place. Clean off the flux when you are done (it will affect performance).

It has been reported that the coaxial feedline length can impact the radiated RF power on some wireless systems. For sure, the coax is very lossy at microwave frequencies, so keep the overall length as short as possible. Some folks have reported that precise coax length tweaks can make a night and day difference. But keep in mind that if the feedline affects the signal, then there is something in the RF system (transmitter, feedline, or antenna) that is not properly impedance matched. I am currently using a 5.2" length, as measured from the tip of the antenna, to the exposed coax end on the XCam2 board.

Watching model R/C videos without sound is rather dull. It adds another dimension to your video clips when you hear the aircraft's engine scream under load or the chatter of servos on a quiet glider. If you insist on skipping the microphone feature then be prepared for a movie audience that quickly loses interest in your filmed masterpieces. At the very least, dub some music onto your silent films.

A microphone can be easily added to the XCam2 transmitter. In my previous projects I posted a schematic of a microphone equipped audio amplifier that worked great. But very few folks wanted to build it, even though it was a ten minute job and cost less than $5. So, to make things easier for everybody, I employed a pre-amplified microphone on this project.

There are several micro-sized audio

solutions that you can use. SuperCircuits sells a tiny amplified microphone

for about $13 (p/n

PA3)

that works fine (it is a bit sensitive though). But I used a little security

camera mic/amplifier from

www.mpja.com.

It is part number 12288-ST and sells for $3.95.

Update: This mic is no longer available.

There are several micro-sized audio

solutions that you can use. SuperCircuits sells a tiny amplified microphone

for about $13 (p/n

PA3)

that works fine (it is a bit sensitive though). But I used a little security

camera mic/amplifier from

www.mpja.com.

It is part number 12288-ST and sells for $3.95.

Update: This mic is no longer available.

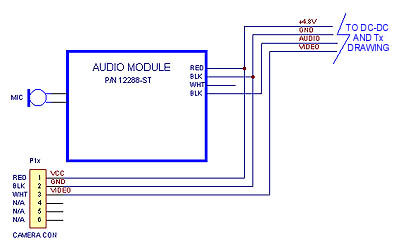

It is advertised as a 12VDC device, but it works fine on 4.8V (lower current too). Be forewarned -- they have an error on their instruction sheet. The pin out is wrong, so follow the order I call out in my schematic. Despite what they think, the pin out is (1) V+, (2) Power Gnd, (3) Audio Gnd, (4) Audio Out. Long ago I sent then a friendly email advising them of the mistake, but I never received a word back from them.

To support the audio feature you must have carefully selected your XCam2 video system with care. I explained the differences in Chapter I.

I purchased the various electronic components from www.digikey.com, www.mouser.com, www.mpja.com, www.hosfelt.com, www.bgmicro.com, www.supercircuits.com, and Radical RC. The BOM (bill-of-materials) is listed below.

Let me remind you that I do not work for, nor represent, ANY supplier of the parts used in RC-CAM. Any reference to a vendor is for your convenience and I do not endorse or profit from any purchase that you make.

Qty |

Description |

Reference |

Source |

PRICE EA |

1 |

Panasonic Color Camera, GP-CX161-53P |

N/A |

Digi-Key P9505-ND or SuperCircuits PC-87XS |

$105.00 |

1 |

Panasonic Color Camera Cable | P1x |

Digi-Key P9507-ND | $3.00 |

1 |

5V to 12V DC-DC Convertor | U1x |

Mouser 580-NME0512S | $8.78 |

2 |

10uF 16V Electrolytic Cap | C1x, C2x |

Mouser 140-MLRL16V10 or equiv. | $0.08 |

1 |

Pactec Enclosure #K-JM22 2.4W x 2.3L x 1.0H |

N/A |

Mouser 616-69313 | $3.09 |

1 |

RG174/U 50 ohm cable, or RG178 50 ohm cable |

N/A |

Hosfelt 60-238 BG Micro ACS1368 |

$0.19/ft |

1 |

4.8V 720mAH NiMH Flat Bat Pack | N/A |

Radical R/C | $12.00 |

Qty |

Description |

Reference |

Source |

PRICE EA |

1 |

Camera Audio Board with Mic | Audio Module |

www.mpja.com #12288-ST |

$3.95 |

|

|

|

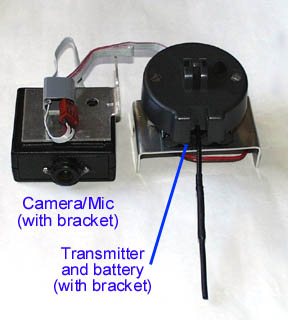

So far we have talked about the bits and pieces of the camera system. Here are some more details to help put it all together.

(1) Plastic Enclosure Layout

A plastic enclosure will house the color camera board and the optional microphone preamp. The Pactec K-JM22 enclosure is the perfect size for the job.

The photo on the right shows the front holes that I drilled to mount the Panasonic Camera board. The larger hole is slightly bigger than the camera lense and the two smaller ones are drilled to accept 2-56 machine screws. Just use the Panasonic camera to mark their locations.

I also made a metal bracket to mount the camera to the Frame of my Century Hawk helicopter. Since everyone will have their own preference on how they make theirs, I will not bore you with the details.

(2) Camera

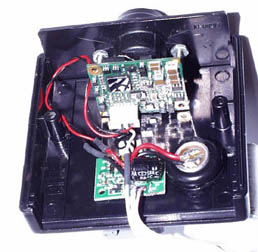

Guts

On my unit the camera enclosure contains the CCD board camera and the audio circuitry. There is plenty of room for these goodies. Just screw the camera in place and mount the audio board using 3M double-sided tape or a little hotmelt glue. Drill a small 1/8" hole and mount the microphone element under it (I used silicone adhesive to hold it).

A 8" long four conductor ribbon cable is used to connect the camera to the transmitter and its DC-DC circuitry. I used a four-pin connector at the camera's end so that I could disconnect the transmitter from it. The ribbon cable connections are made per the following schematic and photo.

|

|

| (3)

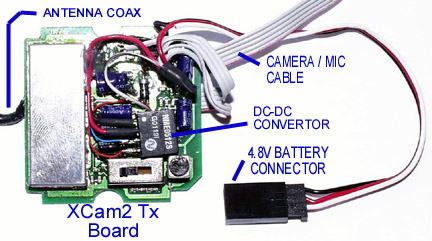

DC-DC Power Supply

The schematic to the power supply is shown below. The DC-DC module, and its two 10uF capacitors, are mounted on the transmitter board as shown in the figure on the right. I used hot melt glue to hold it in place. We also need to add a battery connector and a four conductor cable to the camera enclosure. I'll not to go into the details of how to solder the parts together since each electronic tech has his/her favorite method. |

|

|

|

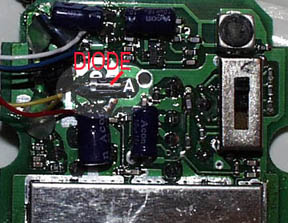

The DC-DC's +12V

power output connection goes to the XCam2 transmitter's power input. It connects

to the diode's Anode as shown in the photo at the left (side marked "A").

I did not install a power switch. Rather, I installed a female servo connector (J1x) so that I can unplug the battery when it is not in use. Pay attention to the polarity or I suggest you look for some good fire insurance. Give your finished wiring a thorough visual inspection.

|

Before applying power to your newly completed circuit please unplug the camera harness power cable. If you made a wiring mistake this expensive part WILL be destroyed.

It's time to get serious. If you have a regulated bench supply then set it for +4.8 VDC (5.0 is fine too). If possible, limit its current to about 500mA. Otherwise you will need to use a 4.8VDC battery pack. But don't apply power just yet.

Here are my recommended

start-up tests:

(5)

System Checkout

The photo on the right shows

you what my custom airborne equipment looked like at this point. With luck,

yours will look similar.

The photo on the right shows

you what my custom airborne equipment looked like at this point. With luck,

yours will look similar.

To check the camera and microphone you will need to install the XCam receiver on your TV or VCR and apply power to everything.

Verify that you have video and audio. If you run into trouble then check that the XCam2 transmitter and receiver are still set to the same channel (A-B-C-D) and that their On/Off switches are "on."

Turn on your model's R/C transmitter and move twenty feet from the XCam equipment. If you find video interference then change the XCam transmitter and receiver to a different A-B-C-D channel. My radio caused some snow on two of the settings.

Perform a video system range test. You should get up to 100 feet inside the house and at least 300 feet while in a clear outdoor area. Verify that the mic works too.

I made a battery cable for the XCam receiver since it normally uses a 12VDC AC wall adapter. I know you don't want to drag 115VAC mains power to the flying field to operate the ground equipment.

You can use your 12V GelCell field (starter) battery to operate the XCam receiver. All you need is a 5.5mm x 2.5mm power plug and some wire. I used a six foot length of 22AWG color coded two conductor cable and soldered the red lead to the center post and the black to the shield lug of the power plug. Solder some alligator clips to the bare ends or use banana plugs if you use a "flight box" power panel. Color code everything or invest in a fire extinguisher!

Whenever your XCam receiver needs power just clip it on to your 12VDC field battery. I recommend that you find a way to avoid reverse voltage issues since the XCam receiver may go up in smoke if you make a connection mistake at the field (oh, that will never happen you say?).

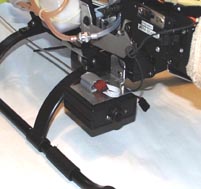

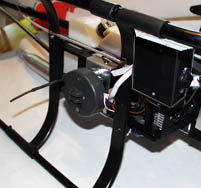

All that remains is to mount the camera system on your R/C model. I'll leave the exact details of this task up to you, since each aircraft (or car/boat/robot) will be different. Just use your creative talents to install the video gear. But to help you out, here are photos of what I did to mount it on my Hawk Heli.

|

|

|

I find that the video antenna works best if it is allowed to hang free under the helicopter. Keep it as vertical as possible and point the antenna tip towards the ground. This will provide an RF pattern that is somewhat directed towards earth, which is where your video receiver will be. My flexible antenna drops below the model after take-off, which provides good range for me. If the antenna is near the model's body or if it doesn't point straight down, the range will decrease. I get reliable reception to at least 400 feet, which is perfect for my video sessions.

I find that video "breakups" are common before takeoff, but once off the ground those issues seem to go away. During flight I get occasional hits of video breakup (flashes or static) due to multipathing interference, but I am happy to say that I rarely see them during my flights. Your results will vary, since your exact installation and environment will affect the video performance. You should be aware that nearby buildings, trees, and other obstructions will drastically reduce the practical range. If you do not get at least 300 feet, with very few video breakups, then something is wrong.

By the way, if you are working with a ground based R/C model (car, boat, robot, etc.) then the coaxial antenna must point up (antenna tip towards sky). This reversal is not only easier to accomplish on such models, but it ensures that the radiated RF pattern is optimal as well.

Longer range can be achieved with better antennas on the video transmitter and receiver, but that part is up to you. If at any time you find video interference then change the XCam2 transmitter and receiver to a different A-B-C-D channel. If anything appears strange DO NOT FLY until you resolve the trouble.

** USE THIS SITE'S INFORMATION AT YOUR OWN RISK! **

Model Helicopters are not toys and should be flown under the supervision of an experienced adult pilot. Our web space sponsors are not responsible for the content of this site and do not endorse radio controlled model helicopters or the use of video camera equipment on them. Our sponsors and/or the web site's authors are NOT responsible for any personal injury or property damage resulting from using the published information.

![]()

Legal Information

© 2001-2015 RC-CAM